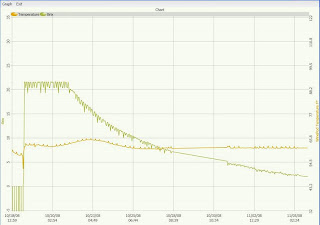

I am sad to report that the temperature sensor on the Winepod stopped working last Thursday. When I checked on the Winepod over the Wine Coach Software, the cooler was on and the temperature read 133F. Since it was clear that the juice was not actually 133F in the Winepod, I turned off the automatic temperature control. The temperature sensor shortly thereafter raised to 150F. It is stuck at 150F. On Sunday, the brix read just under 1.0, so I decided to rack and not take any more chances with the Wine Pod temp control. The actual temperature of the juice was 60F. After email and phone correspondence with Greg Snell and Fred Hekking of ProVina, it seems most likely that the thermistor has failed. Fred will send out a temporary test thermistor which I will wire into the system to confirm that diagnosis. Considering the cost to ship the WinePod to and from San Jose easily approaches $1000, Fred will probably make the repair in person on his next trip to the east coast. Hopefully the therm...