Secondary Fermentation Continues

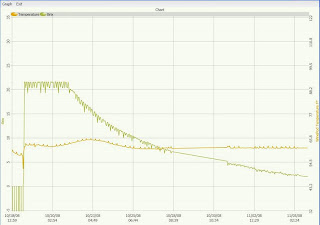

At three weeks into the second phase of fermentation, the Riesling wine is beginning ever so slightly to clear. Last weekend I had a scare when I logged into the server and saw that the air temperature in the basement was 52 degrees. The furnace went out the night before and the temperature was in free fall. I made a brief trip up to the Shier and re-started the furnace. I am wondering if poor ventilation and the high level of carbon dioxide was affecting the oil furnace ignition. The thermometers on the carboys were each at 54 degrees. Again, the D47 yeast survives down to 50 degrees. Close call. When I returned this weekend the carboy temperatures were back up to 57 degrees and the wine was still bubbling up. I measured the SG on a wine sample from the third carboy. It measured 0.999. So far, so good. I will add oak chips to the third carboy in four weeks. If all goes according to plan, I will rack and cold stabilize in five weeks. I also tried to measure the free SO2 level using a...