Thermistor Fixed on Winepod

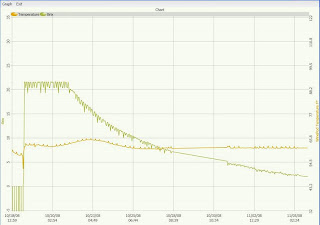

This past Sunday night I made a trip to the Shier to make the repair to the temperature control mechanism on the Winepod . The thermistor, a little temperature sensing resistor attached to the vessel burned out right at the conclusion of our primary fermentation. Fred Hekking of ProVina walked me through the repair while he was driving back from a weekend vacation in Northern California. The repair involved using a soldering iron to melt the polypropylene material in which the old thermistor was buried. I melted the poly, destroyed the old thermistor and carved a trench for the new thermistor. Then I used my finger to push the melted poly over the new thermistor. Fred said that the thermistor was rated to 700 degrees, so I was not afraid that the hot plastic would destroy the replacement part. When the repair was complete, I turned the unit on and it accurately measured the ambient tank temperature. Success! The wine continues to dry down and clear in the carboys. A dark se...